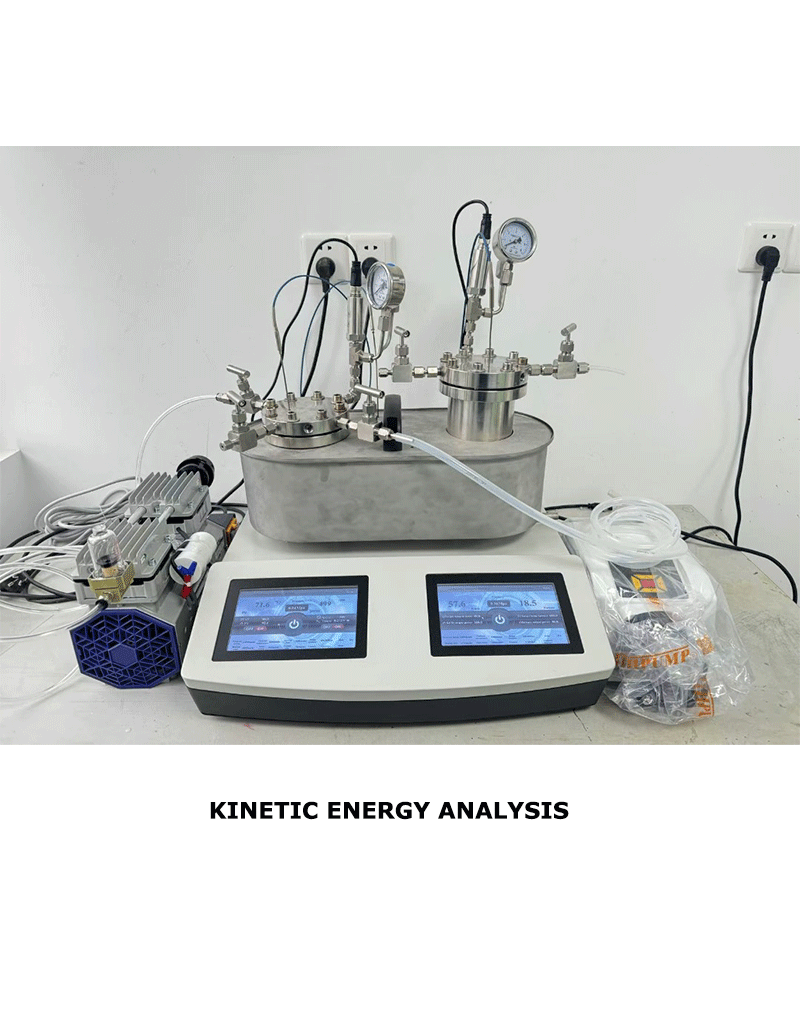

CUSTOM KINETIC FORCE ANALYSIS REACTOR SYSTEM

Our Custom Reactor System is specifically engineered for kinetic force-related research and experimental analysis. Designed with precision, high-quality materials, and integrated digital monitoring, this system is ideal for advanced lab-based chemical or biochemical reaction testing under controlled thermal and pressure conditions.

System Components & Features

- Water Bath (Separate or Combined Options Available)

- Temperature Range: 0–80 °C

- Ensures precise thermal regulation for reactor operations.

- Optional standalone or integrated setup based on lab requirements.

- Buffer Tank (Material: SUS316L Stainless Steel)

- Volume: 1 Liter

- Max Pressure: 6000 kPa

- Digital Pressure Gauge

- Accuracy: ±0.01

- Range: >6000 kPa

- Data Logging Enabled

- Digital Thermocouple

- Temperature Range: 0–100 °C

- Real-time Monitoring & Data Logging

- Gas & Liquid Interfaces

- CO₂ Inlet with High-Precision Needle Valve & Accessories

- Reactor Inlet/Outlet Ports with Needle Valve Control

- Reactor Tank (Material: SUS316L with Quartz Inner Liner)

- Volume: 500 ml

- Working Pressure: 2–3 bar

- Digital Pressure Gauge

- Accuracy: ±0.01

- Range: >6000 kPa

- Data Logging Enabled

- Digital Thermocouple

- Temperature Range: 0–100 °C

- Data Logging for Enhanced Process Control

- Liquid Feed System

- Inlet with Peristaltic Pump for Controlled Flow

- Vacuum Management

- Outlet Port for Vacuum Pump with Needle Valve Connector

- Integrated Vacuum Pump Included

- Mixing System

- Built-in Magnetic Stirrer for Homogeneous Mixing

Key Benefits

- Durable, corrosion-resistant SUS316L build suitable for high-pressure research environments

- Real-time data acquisition for pressure and temperature, ideal for kinetic studies and system modeling

- Flexible configuration to suit both standalone or integrated use in existing lab setups

- Safety-focused design with precision valves and monitoring instruments